From shaft extensions to gripper kits and pan-tilt brackets, there are all sorts of hardware and components you can add to your servo to augment and improve its functionality. It is worth noting that any measurement between no load and the stall torque spec will more than likely slow down the operating speed listed.Ī servo on its own cannot do much so accessories connected to the drive shaft are necessary to get the most out of your servo. 16 seconds with no load, and has a higher torque limit of 4.1kg/cm. At 6V, the high end of the test voltage, the servo can move 60° at a speed of. Also operating at 4.8V, this servo motor can drive a load up to 3.3kg/cm ( Stall Torque). 21 seconds without any limiting force factors (load). The datasheet shows that at 4.8V the servo can move 60° at a speed of. The first thing to notice is that this servo lists a Test Voltage, often labeled Operating Voltage, from 4.8V to 6V. We've pulled out a few key power specs from this datasheet for the Hitec HS-422 (Standard Size) servo. Let's take a look at an example :Īn exerpt from a datasheet for the Hitec HS-422 It is important to check the specifications of the servo you intend to use to make sure your power supply has the proper voltage range and can deliver enough current to move the servo with your load attached. When unloaded, a common hobby servo can pull as little as 10mA, but larger servos under load can pull in excess of an Ampere or more. More important than voltage is the current draw a servo can pull while moving and with a load attached.

While(!esp.Depending on the size and torque output of your servo the input voltage will vary, but most hobby servos will work fine with 5V from your preferred microcontroller or battery circuit. SendData("AT+CWJAP=\"WiFiName\",\"WiFi Password\"\r\n", 2000, DEBUG) //Enter WiFi name and password #define servopin 8 //connect servo on pin 8

#SERVO MOTOR PROJECTS SERIAL#

#define DEBUG true //This will display the ESP8266 messages on Serial Monitor SoftwareSerial esp(2,3) // set ESP8266 Receiver pin = 2, and transmitter pin = 3

#SERVO MOTOR PROJECTS SOFTWARE#

#include //Including the software serial library Not only ESP8266 but you can also use ESP32 for designing IoT projects. Hence, we have successfully set up a local server using ESP8266 for controlling the servo through a webpage.

Now after this, navigate to your browser and open the web page that you created earlier and scroll the button to move the servo. Your serial monitor will show you the IP address of your ESP8266. Make the required changes in this and upload it to Arduino IDE.

#SERVO MOTOR PROJECTS CODE#

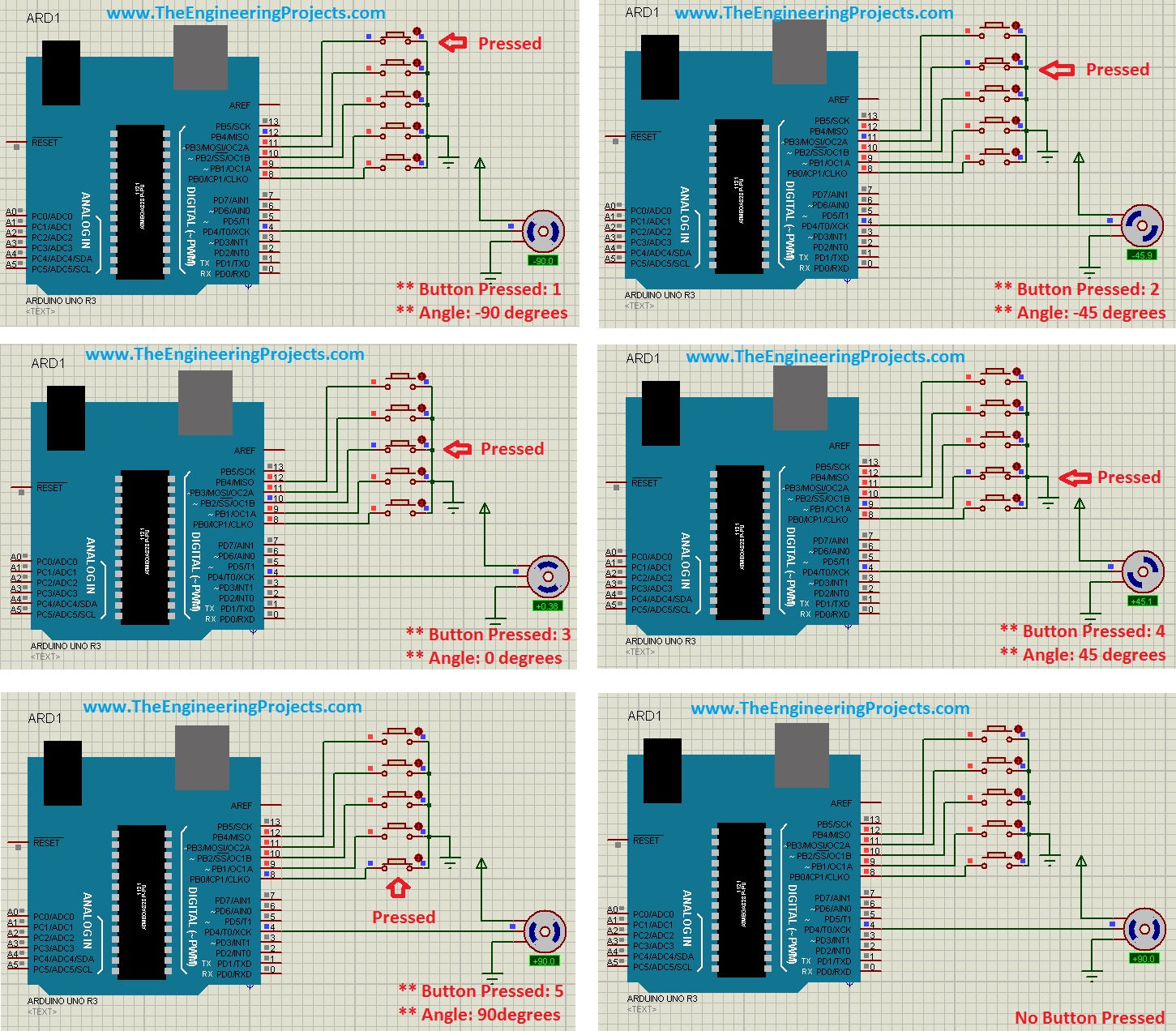

The complete HTML code for controlling the Servo using Arduino and ESP8266 is given below: Web controlled Servo Control Servo Via Web Page Enter ESP8266 IP Address: Scroll it to rotate servo $.ajaxSetup( We are using Arduino IDE for Programming ESP8266 NodeMCU. By using this webpage, you can control the Servo from anywhere in the world over the internet. The servo motor will be controlled by moving the slider on a webpage. We will develop a small webpage using HTML and javascript and then send commands to Arduino using the Wi-Fi module. ESP8266 is establishing a connection between the servo motor and the web browser through the IP address.

0 kommentar(er)

0 kommentar(er)